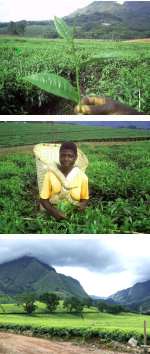

Lujeri Tea Estates produce some 12,500 tones of made tea from 55,000 tons of green leaf in its four factories. Smallholder farmers currently account for 15% of this production.

The company has 3,300 hectare under tea as well as 1,300 hectares of blue gum and 700 hectares of Macadamia orchards.

Tea is sold both by forward contract and on the Limbe auction, where Lujeri teas are regularly available.

Field

Tea bushes are plucked by hand, at intervals of between 7 and 14 days, depending on the season. Great care is taken to ensure that only the top three leaves and the bud are plucked, as this ensures the quality of the final product.

Plucked green leaf is quality checked prior to being collected by tractor trailer from the company's fields and transported to the factories.

Care is taken to prevent bruising and physical damage to the leaf in transit and during unloading into the withering troughs.

Withering

Green leaf is spread evenly on the withering troughs, where air is introduced to reduce the moisture content. Here, physical and chemical wither takes place under controlled conditions.

When the leaf has reached the desired moisture content the leaf is weighed and sent to the rolling room for processing.

Cutting

The withered leaf is cut to the final size in one of two processes (CTC or LTP). The cut tea is known as dhool and the cell disruption (cutting) process and exposure to oxygen generates heat which accelerates the enzyme activity and initiates the natural oxidation process.

Controlled oxidation

The oxidation process is closely monitored to establish the optimum point where all the desirable chemicals contained within the leaf peak. The dhool changes colour during this period and takes of the characteristic copper brown hue.

Drying

Once the oxidisation process is complete it is necessary to arrest the enzyme activity and to reduce the moisture content of the dhool down to less then 3%. This is achieved by passing the tea through a fluidised bed dryer where the tea particles are exposed to hot air. Enzyme activity ceases when particle temperature exceeds 35 degrees C.

Fibre Removal and Sorting

Tea exiting the dryer is perfectly drinkable and only requires to be cleaned and size graded. The stalk and fibre is removed through a simple process involving creation of static electricity which attracts charged fibres onto PVC rollers. The size classification is achieved by passing the black tea through a series of screens which separate it into the various grades.

Packing

Teas in the various grades are then packed into foiled lined paper sacks to customer specifications. Paper sacks are then palletised (20 per pallet) and prepared for export for transport to market.

Distribution

Teas are either transported break bulk to Blantyre for sale on the local Limbe Auction or containerised on the estate and trucked or sent by rail to the ports for export to the customer.

site developed by optim8